20

Cooling dress for hot days

Heat exchangers for Wendelstein 7-X pipes

The technical challenge faced by the mechanical engineering

company was the combination of high power input, tight tolerances

and the use in ultra-high vacuum. The cooling system is

designed for a power input of 50 to 100 kW/m2 and functions as

a heat exchanger: cold water flows in four millimeter-thin tubes,

which in turn are located in eight millimeter-thick tubes. The

return flow then takes place in the space between the two pipes.

This design allows manufacture of differently shaped port liners

– round, rectangular or oval – that fit precisely into the narrow

installation spaces of 15 to 20 millimeters.

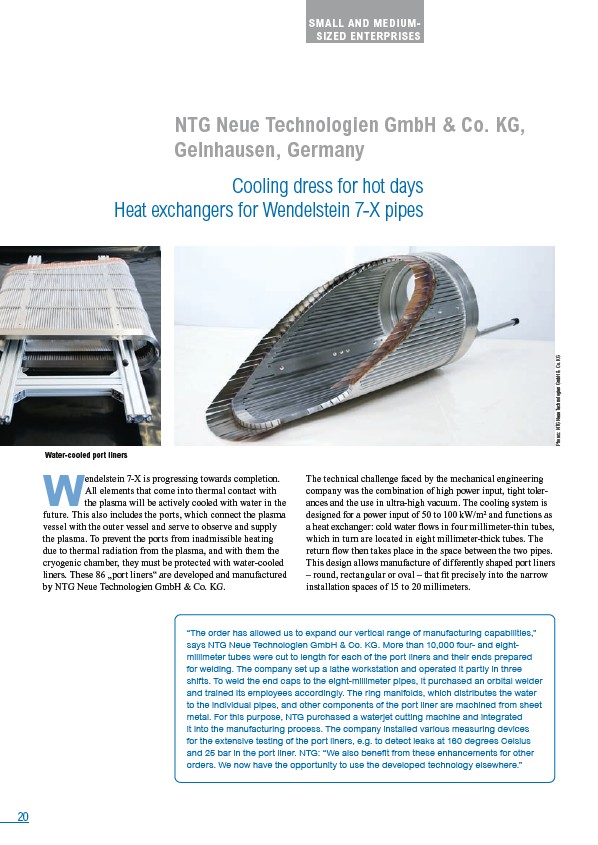

Wendelstein 7-X is progressing towards completion.

All elements that come into thermal contact with

the plasma will be actively cooled with water in the

future. This also includes the ports, which connect the plasma

vessel with the outer vessel and serve to observe and supply

the plasma. To prevent the ports from inadmissible heating

due to thermal radiation from the plasma, and with them the

cryogenic chamber, they must be protected with water-cooled

liners. These 86 „port liners“ are developed and manufactured

by NTG Neue Technologien GmbH & Co. KG.

SMALL AND MEDIUM-

SIZED ENTERPRISES

NTG Neue Technologien GmbH & Co. KG,

Gelnhausen, Germany

“The order has allowed us to expand our vertical range of manufacturing capabilities,”

says NTG Neue Technologien GmbH & Co. KG. More than 10,000 four- and eightmillimeter

tubes were cut to length for each of the port liners and their ends prepared

for welding. The company set up a lathe workstation and operated it partly in three

shifts. To weld the end caps to the eight-millimeter pipes, it purchased an orbital welder

and trained its employees accordingly. The ring manifolds, which distributes the water

to the individual pipes, and other components of the port liner are machined from sheet

metal. For this purpose, NTG purchased a waterjet cutting machine and integrated

it into the manufacturing process. The company installed various measuring devices

for the extensive testing of the port liners, e.g. to detect leaks at 160 degrees Celsius

and 25 bar in the port liner. NTG: “We also benefit from these enhancements for other

orders. We now have the opportunity to use the developed technology elsewhere.”

Water-cooled port liners

Photos: NTG Neue Technologien GmbH & Co. KG