37

Fraunhofer-Institut für Gießerei-, Composite-

und Verarbeitungstechnik, Augsburg, Germany

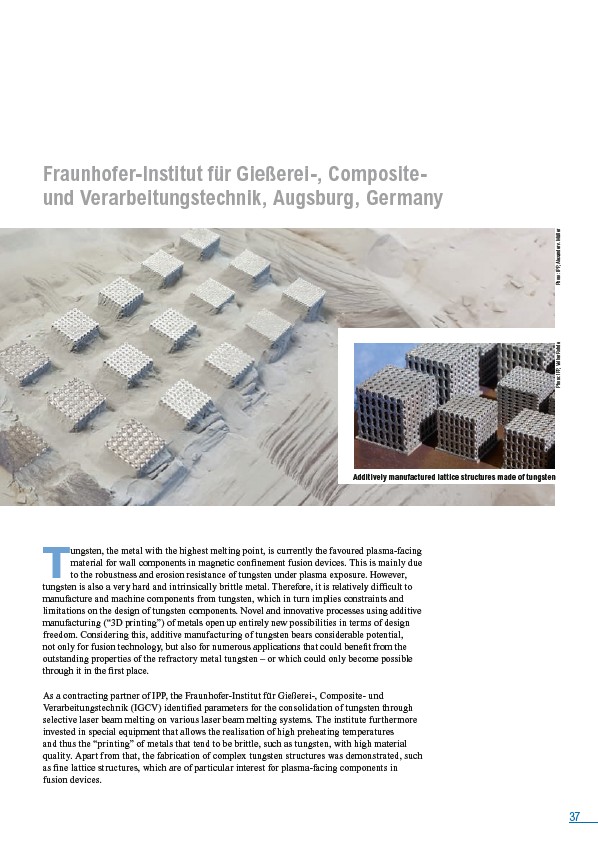

Additively manufactured lattice structures made of tungsten

Tungsten, the metal with the highest melting point, is currently the favoured plasma-facing

material for wall components in magnetic confinement fusion devices. This is mainly due

to the robustness and erosion resistance of tungsten under plasma exposure. However,

tungsten is also a very hard and intrinsically brittle metal. Therefore, it is relatively difficult to

manufacture and machine components from tungsten, which in turn implies constraints and

limitations on the design of tungsten components. Novel and innovative processes using additive

manufacturing (“3D printing”) of metals open up entirely new possibilities in terms of design

freedom. Considering this, additive manufacturing of tungsten bears considerable potential,

not only for fusion technology, but also for numerous applications that could benefit from the

outstanding properties of the refractory metal tungsten – or which could only become possible

through it in the first place.

As a contracting partner of IPP, the Fraunhofer-Institut für Gießerei-, Composite- und

Verarbeitungstechnik (IGCV) identified parameters for the consolidation of tungsten through

selective laser beam melting on various laser beam melting systems. The institute furthermore

invested in special equipment that allows the realisation of high preheating temperatures

and thus the “printing” of metals that tend to be brittle, such as tungsten, with high material

quality. Apart from that, the fabrication of complex tungsten structures was demonstrated, such

as fine lattice structures, which are of particular interest for plasma-facing components in

fusion devices.

Photo: IPP, Volker Rohde Photo: IPP, Alexander v. Müller