6

LARGE

CORPORATIONS

MAN Energy Solutions SE,

Deggendorf, Germany

“The Mona Lisa of the art of welding” *

The plasma vessel of the Wendelstein 7-X

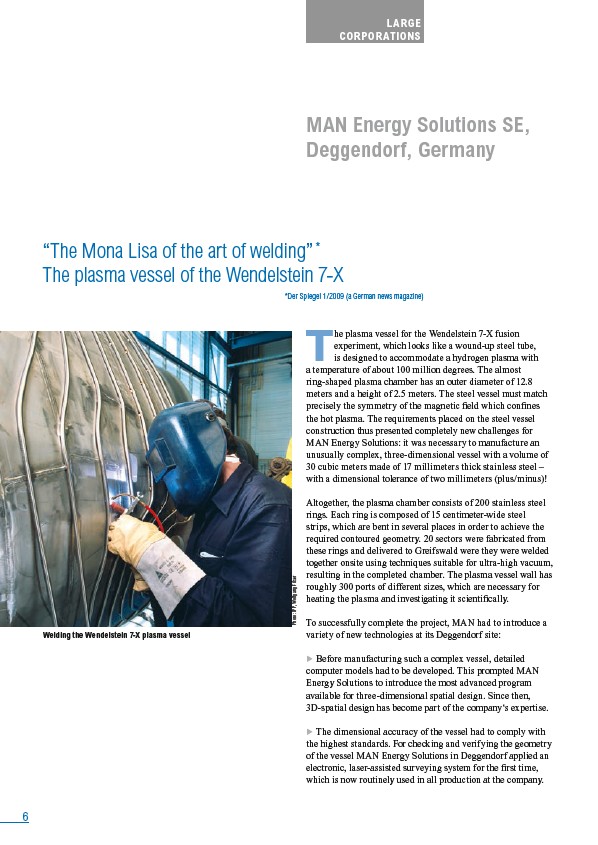

The plasma vessel for the Wendelstein 7-X fusion

experiment, which looks like a wound-up steel tube,

is designed to accommodate a hydrogen plasma with

a temperature of about 100 million degrees. The almost

ring-shaped plasma chamber has an outer diameter of 12.8

meters and a height of 2.5 meters. The steel vessel must match

precisely the symmetry of the magnetic field which confines

the hot plasma. The requirements placed on the steel vessel

construction thus presented completely new challenges for

MAN Energy Solutions: it was necessary to manufacture an

unusually complex, three-dimensional vessel with a volume of

30 cubic meters made of 17 millimeters thick stainless steel –

with a dimensional tolerance of two millimeters (plus/minus)!

Altogether, the plasma chamber consists of 200 stainless steel

rings. Each ring is composed of 15 centimeter-wide steel

strips, which are bent in several places in order to achieve the

required contoured geometry. 20 sectors were fabricated from

these rings and delivered to Greifswald were they were welded

together onsite using techniques suitable for ultra-high vacuum,

resulting in the completed chamber. The plasma vessel wall has

roughly 300 ports of different sizes, which are necessary for

heating the plasma and investigating it scientifically.

To successfully complete the project, MAN had to introduce a

variety of new technologies at its Deggendorf site:

▶ Before manufacturing such a complex vessel, detailed

computer models had to be developed. This prompted MAN

Energy Solutions to introduce the most advanced program

available for three-dimensional spatial design. Since then,

3D-spatial design has become part of the company‘s expertise.

▶ The dimensional accuracy of the vessel had to comply with

the highest standards. For checking and verifying the geometry

of the vessel MAN Energy Solutions in Deggendorf applied an

electronic, laser-assisted surveying system for the first time,

which is now routinely used in all production at the company.

Welding the Wendelstein 7-X plasma vessel

*Der Spiegel 1/2009 (a German news magazine)

Photo: IPP, Wolfgang Filser