30

SMALL AND MEDIUM-

SIZED ENTERPRISES

Bauer Profiltechnik GmbH,

Neckarwestheim, Germany

Promotional dummy

Profile-frame polygon for trial assemblies – a second ASDEX Upgrade

Bauer Profiltechnik, a specialist in tailor-made work

stations, has developed an innovative, 3.5-meter-high

and 4.5-meter-wide frame that accommodates the fastening

points – and on this, the two-ton components.

The support system is a 16-cornered polygon. From

90 x 90 millimeter thick profile struts, the designers

assembled 8 x 32 connections at an exact angle

of 11.25 degrees each. Thereby, IPP required

a deviation tolerance of less than one millimeter.

“The result is a small masterpiece

even for us,” Uwe Wehle, Managing Director

of Bauer Profiltechnik, sums up the

high-publicity showcase project. “Thanks

to the modular and strut-like construction

method in which we designed and manufactured

the frame, the mock-up is also

designed to be highly flexible in terms of

adaptation, adjustment or extension without

the need for special tools and combined

with enormous time savings.”

During the entire process, the material was machined

at a temperature of 20 degrees Centigrade

from the first to the last work step. “In this way, we

were able to achieve a tolerance accuracy of 0.5 millimeters

and to align the frame in Garching with an accuracy

of up to two millimeters,” the company says on its

website. “With the polygon we realized for IPP, we have

created a project that illustrates the wide-ranging design

options and possible applications of profile frame

solutions. Such tailor-made solutions can be applied to

almost any work and activity field in any industry and

optimize the processes there.”

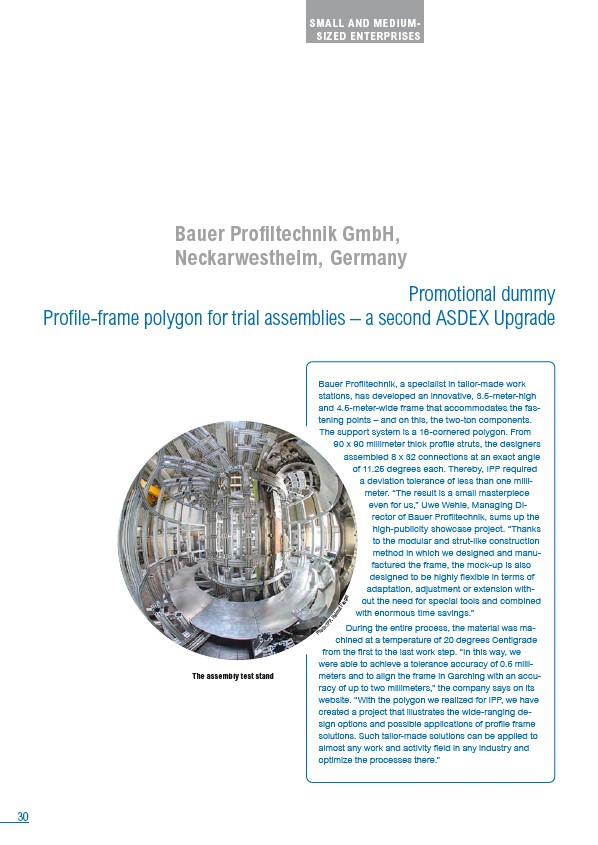

The assembly test stand

Photo: IPP, Helmut Faugel