26

RASI Maschinenbau GmbH,

Illingen, Germany

A colossal cable harness

The superconducting bus system for Wendelstein 7-X

The 70 superconducting coils of Wendelstein 7-X must be

electrically and hydraulically connected to each other as

well as to the current leads. This is done by 124 threedimensionally

pre-formed superconductors. Thin filaments of

the niobium-titanium superconductor are embedded in copper

wires that are twisted into a cable. Liquid helium for cooling at

the required temperature of -270 degrees Celsius flows between

the individual wires. The cable itself is enclosed in a heliumtight

aluminum case. Unlike the wire harness in a road vehicle,

for example, the shape of the connecting lines cannot be

adjusted on site because the superconductor cable is not flexible.

The cables thus have to be prefabricated with a high accuracy

of just a few millimeters. This made it necessary to build and

qualify a computer-controlled bending machine.

The company RASI and the Forschungszentrum Jülich have

jointly developed an instrument that allows bends to be realized

in two directions. Normally, a variable bending direction is

made possible by rotating the piece about its axis. Here, however,

we were dealing with pre-formed parts of several meters

in length, which, during rotation would have swung freely in

space, even below floor level. The novel two-directional bending

machine allows the piece always to be turned upwards, and

hence makes the whole manufacturing process possible at all.

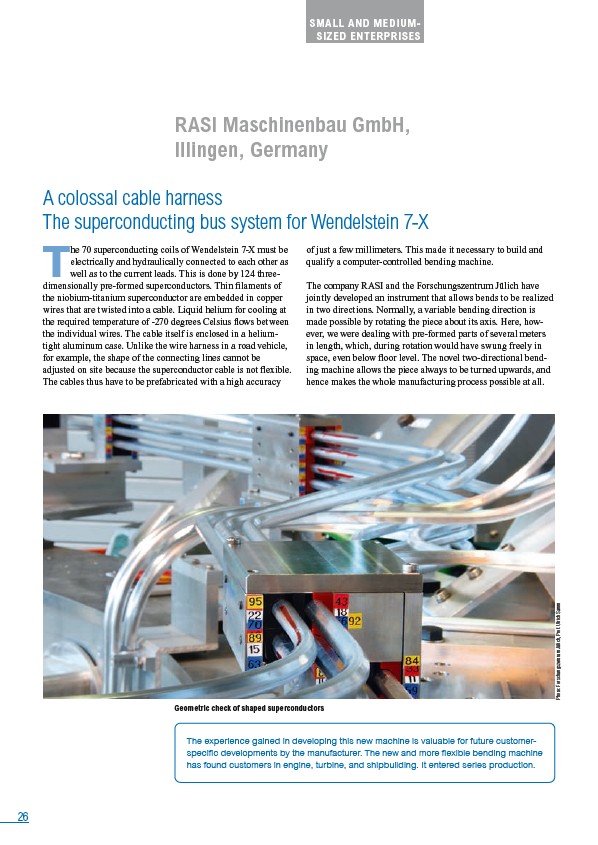

Geometric check of shaped superconductors

The experience gained in developing this new machine is valuable for future customer-

specific developments by the manufacturer. The new and more flexible bending machine

has found customers in engine, turbine, and shipbuilding. It entered series production.

Photo: Forschungszentrum Jülich, Prof. Ulrich Samm

SMALL AND MEDIUM-

SIZED ENTERPRISES