36

Hot off the 3D printer

Additive manufacturing

of tungsten by means of selective

laser beam melting

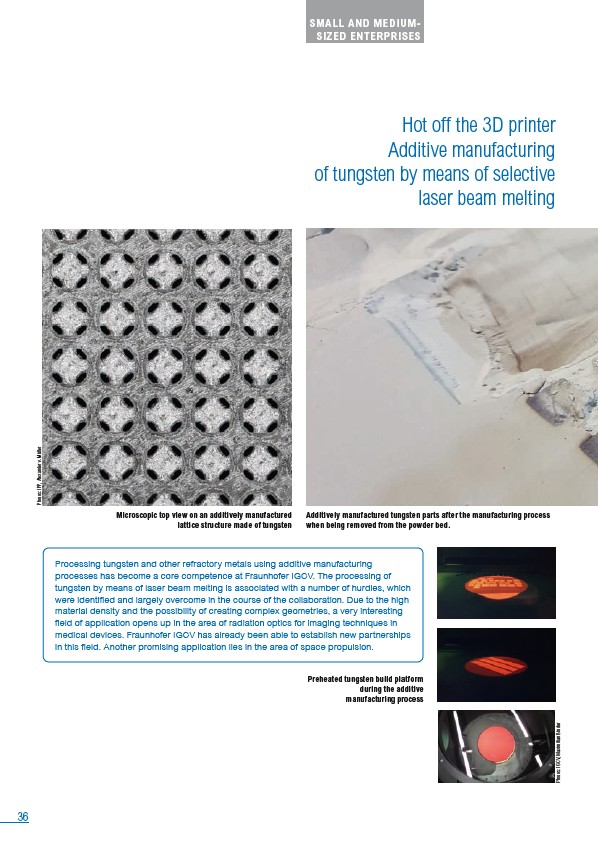

Additively manufactured tungsten parts after the manufacturing process

when being removed from the powder bed.

Microscopic top view on an additively manufactured

lattice structure made of tungsten

Processing tungsten and other refractory metals using additive manufacturing

processes has become a core competence at Fraunhofer IGCV. The processing of

tungsten by means of laser beam melting is associated with a number of hurdles, which

were identified and largely overcome in the course of the collaboration. Due to the high

material density and the possibility of creating complex geometries, a very interesting

field of application opens up in the area of radiation optics for imaging techniques in

medical devices. Fraunhofer IGCV has already been able to establish new partnerships

in this field. Another promising application lies in the area of space propulsion.

Preheated tungsten build platform

during the additive

manufacturing process

Photos: IGCV, Maximilian Binder

Photos: IPP, Alexander v. Müller

SMALL AND MEDIUM-

SIZED ENTERPRISES