31

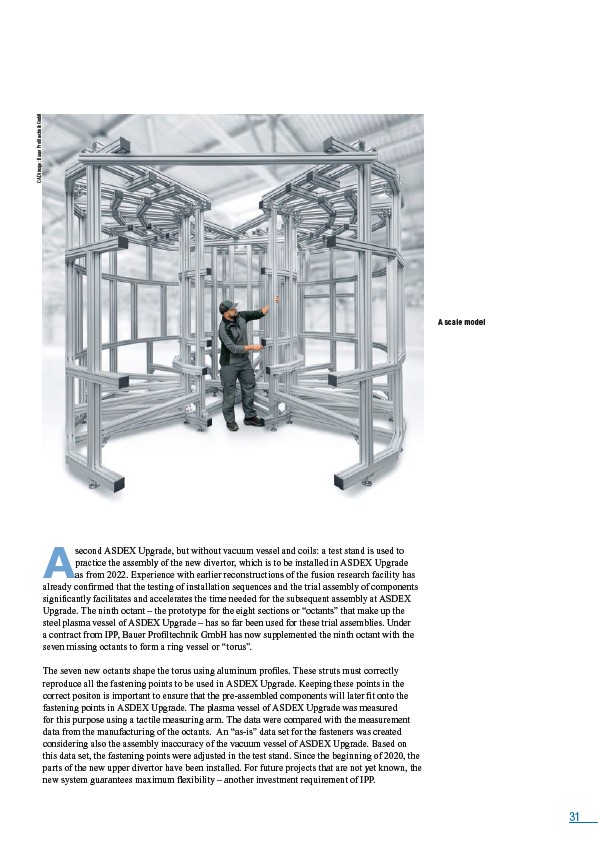

CAD image: Bauer Profiltechnik GmbH

A scale model

A second ASDEX Upgrade, but without vacuum vessel and coils: a test stand is used to

practice the assembly of the new divertor, which is to be installed in ASDEX Upgrade

as from 2022. Experience with earlier reconstructions of the fusion research facility has

already confirmed that the testing of installation sequences and the trial assembly of components

significantly facilitates and accelerates the time needed for the subsequent assembly at ASDEX

Upgrade. The ninth octant – the prototype for the eight sections or “octants” that make up the

steel plasma vessel of ASDEX Upgrade – has so far been used for these trial assemblies. Under

a contract from IPP, Bauer Profiltechnik GmbH has now supplemented the ninth octant with the

seven missing octants to form a ring vessel or “torus”.

The seven new octants shape the torus using aluminum profiles. These struts must correctly

reproduce all the fastening points to be used in ASDEX Upgrade. Keeping these points in the

correct positon is important to ensure that the pre-assembled components will later fit onto the

fastening points in ASDEX Upgrade. The plasma vessel of ASDEX Upgrade was measured

for this purpose using a tactile measuring arm. The data were compared with the measurement

data from the manufacturing of the octants. An “as-is” data set for the fasteners was created

considering also the assembly inaccuracy of the vacuum vessel of ASDEX Upgrade. Based on

this data set, the fastening points were adjusted in the test stand. Since the beginning of 2020, the

parts of the new upper divertor have been installed. For future projects that are not yet known, the

new system guarantees maximum flexibility – another investment requirement of IPP.