24

SMALL AND MEDIUM-

SIZED ENTERPRISES

Micrometer

precision work

Mechanical machining

of the central ring

CLP Srl,

Borgo San Dalmazzo, Italy

Working on the Wendelstein

7-X central

ring has opened completely

new areas of

work for the company,

as well as additional

fields for contracts.

The pre-machining

of coil components

for the international

experimental reactor

ITER and the final

machining of coils for

the Japanese-European

fusion device JT-

60SA, for which CLP

also designed and

manufactured the coil

transport kits – these

are all activities that

have resulted from the

cooperation with IPP.

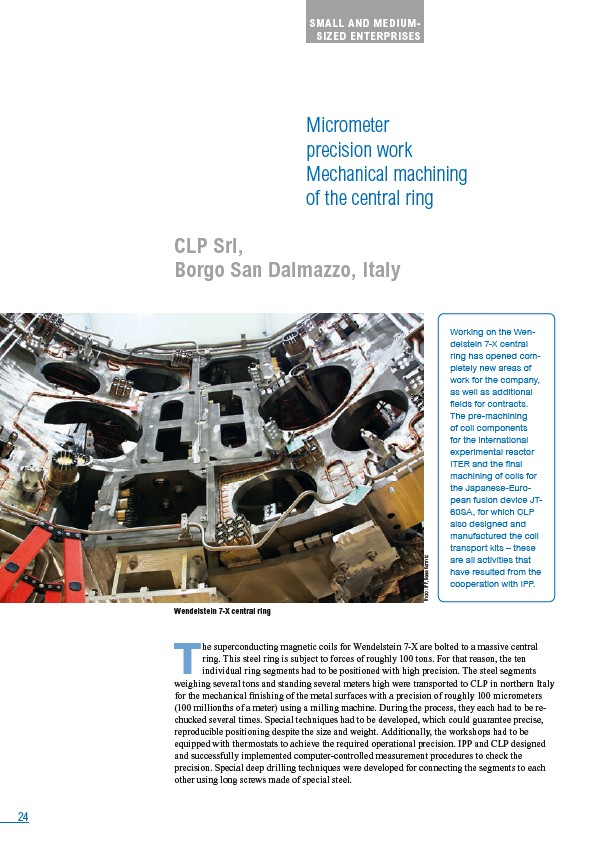

Wendelstein 7-X central ring

Photo: IPP, Beate Kemnitz

The superconducting magnetic coils for Wendelstein 7-X are bolted to a massive central

ring. This steel ring is subject to forces of roughly 100 tons. For that reason, the ten

individual ring segments had to be positioned with high precision. The steel segments

weighing several tons and standing several meters high were transported to CLP in northern Italy

for the mechanical finishing of the metal surfaces with a precision of roughly 100 micrometers

(100 millionths of a meter) using a milling machine. During the process, they each had to be rechucked

several times. Special techniques had to be developed, which could guarantee precise,

reproducible positioning despite the size and weight. Additionally, the workshops had to be

equipped with thermostats to achieve the required operational precision. IPP and CLP designed

and successfully implemented computer-controlled measurement procedures to check the

precision. Special deep drilling techniques were developed for connecting the segments to each

other using long screws made of special steel.